new

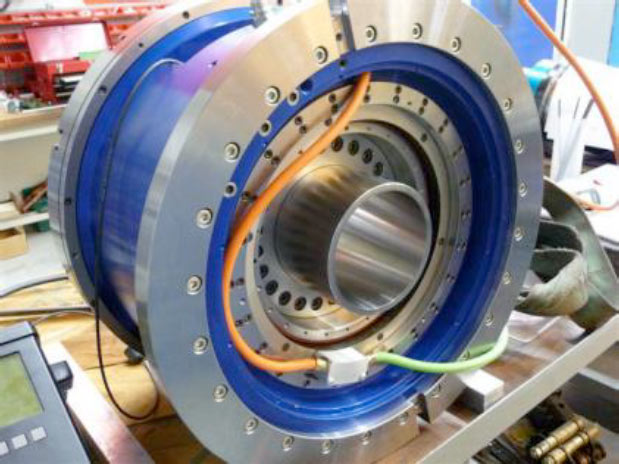

Electric motor for HV

Designing and manufacturing 13 prototypes for hybrid drivetrain. The motors were used on their testbeds and mounted in the cars. The main challenge was the embedment, so the choice of material turned to was aluminium, albeit with its associated dilation problems. The motor was obviously cooled down with the use of water via the vehicle system, and the mechanics were designed to control the temperature variations.

Direct-driven rotating plate

Rotary Table prototype for use as a 4th axis on a machining centre. As it was important to reduce the encumbrance; the table is directly driven by a torque motor (no gearbox). A parking break blocks the table during operations. The integrated encoder is used for indexing and simple rotating operations.

Machining centre for spindles

A replacement spindle for MANDELLI’s machining centre. From the original machine model, we built a spindle with the same interfaces (fluids, connections, mechanical and electrical characteristics) to make replacing the spindle transparent for the end user, but the internal mechanics were "Designed by EREM".